Warehouse Management System Processes Part 2: PutAway

Last year, we wrote about “The right putaway process”. There, we analyzed the different ways of doing the putaway, the best practices, and its benefits. A Warehouse Management System (WMS) plays a pivotal role in streamlining this process, ensuring that goods are stored correctly and are easily retrievable when needed. In this article, I will review the features a WMS should have to enhance the efficiency and accuracy of the putaway or check-in process.

WMS Features for an Optimal Putaway

For an optimal put-away process, a Warehouse Management System (WMS) should have the following features:

Advanced Location Management

It refers to the ability to define and manage various storage locations within the warehouse, such as racks, shelves, bins, and bulk storage areas. The WMS should support zoning and segmentation to organize inventory based on product characteristics, turnover rates, and storage requirements.

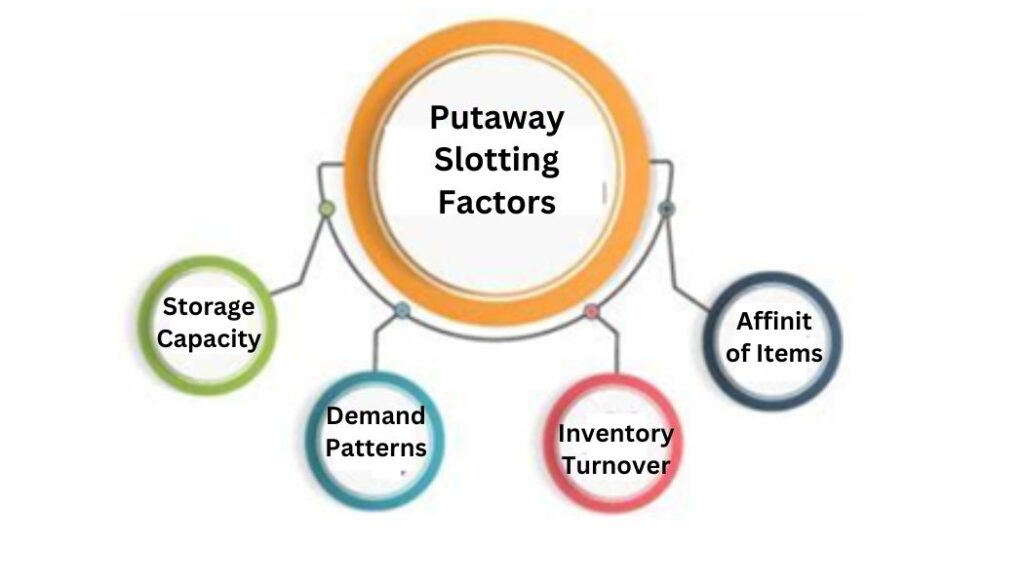

Dynamic Slotting

The WMS should incorporate automated slotting algorithms to assign goods to the most appropriate storage locations based on factors like size, weight, frequency of access, and compatibility with other stored items, and the flexibility to adjust slotting rules as inventory and demand patterns change.

Barcode and RFID Scanning

Integration with barcode and RFID scanning technologies is a must for accurate and efficient identification and tracking of goods during the putaway process. Real-time data capture to update inventory records and confirm task completion.

Task Management and Prioritization

Generation of putaway tasks must be done with clear instructions for warehouse staff, including the Generation of putaway tasks must be done with clear instructions for warehouse staff, including the destination location and any special handling requirements. It must also prioritize tasks based on urgency, order deadlines, or other business rules.

Real-Time Inventory Visibility

The system must provide up-to-date visibility into the inventory levels and locations, allowing for quick retrieval and efficient space utilization. It should also support inventory tracking methods like batch, lot, and serial number tracking.

Integration with Other Systems

The WMS must provide seamless integration with other systems, such as ERP (Enterprise Resource Planning), TMS (Transportation Management System), and order management systems for coordinated operations across the supply chain, with data synchronization to ensure consistency and accuracy across systems.

Reporting and Analytics

The WMS must provide comprehensive reporting tools to monitor the efficiency of the putaway process, identify bottlenecks, and track key performance indicators (KPIs), and have analytics capabilities to derive insights and make data-driven decisions for process improvement.

User-Friendly Interface

The system must have an intuitive user interface for ease of use by warehouse staff, reducing training time and the risk of errors, and support for mobile devices and handheld terminals for on-the-go access to tasks and information.

Scalability and Customization

The system should have the ability to scale and adapt to the changing needs of the warehouse, including support for additional locations, increased inventory, and new business processes.

Conclusion

Laceup WMS products incorporate all the features required to optimize the putaway process, leading to optimized space utilization, reduced handling times, and improved overall warehouse performance.

If you want to learn more, give us your information to schedule a meeting.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. There is a lot of relevant information on our channel. Check this short on a live demo of the checking-in process.

Sorry, the comment form is closed at this time.