Warehouse Safety Standards: A Comprehensive Guide

Warehouse safety is critical for protecting employees, inventory, and assets while maintaining smooth operations. This guide covers essential safety standards, practices, and regulations to help warehouses operate safely and efficiently.

Understanding Warehouse Safety

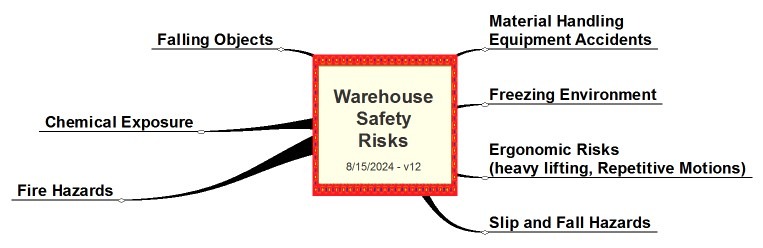

As explained in our recent article about a safety warehouse environment, warehouse safety involves policies, procedures, and equipment designed to prevent accidents and injuries. This includes compliance with regulatory standards, risk assessment, employee training, and continuous improvement. The most common risks to consider for prevention are:

Regulatory Compliance

There are 3 regulatory compliance that warehouse owner must consider.

Occupational Safety and Health Administration (OSHA)

- OSHA Standards: OSHA provides regulations specific to warehouse operations. Key standards include hazard communication, forklift safety, and proper use of personal protective equipment (PPE).

- Reporting and Recordkeeping: Maintain accurate records of workplace injuries, illnesses, and inspections as required by OSHA.

Fire Safety Codes

- National Fire Protection Association (NFPA): Follow NFPA standards for fire prevention, emergency exits, and fire suppression systems.

- Local Fire Codes: Adhere to state and local fire safety regulations, including proper storage of flammable materials.

Environmental Regulations

- Hazardous Materials Handling: Comply with Environmental Protection Agency (EPA) guidelines for storage, disposal, and spill response of hazardous materials.

- Waste Management: Implement recycling and waste disposal practices that meet environmental regulations.

Specific Safety Areas Safety Measures

This section lists the most common preventive measures implement to enforce warehouse safety, grouped by warehouse areas.

| Forklift Safety: Operator training and certification Vehicle inspections Clear aisles and designated pedestrian walkways Load securement Pedestrian Safety: Designated walkways Audible and visual warnings High-visibility clothing Loading and Unloading: Proper lifting techniques Back support equipment Secure loads | Warehouse Layout: Clear aisles and exit routes Adequate lighting Emergency exits Fire Safety: Fire extinguishers Smoke detectors Sprinkler systems Flammable materials storage |

A Comprehensive Guide to safe warehouse Operation

Warehouse Design and Layout

Safe Layout Planning

- Clear Aisles: Ensure aisles are wide enough for equipment and personnel to pass safely, minimizing the risk of collisions.

- Proper Signage: Use signs to indicate hazards, emergency exits, and restricted areas.

Racking and Storage Systems

- Load Limits: Adhere to load limits for racking systems to prevent collapses.

- Safe Stacking: Stack materials securely to avoid tipping or falling.

Lighting and Ventilation

- Adequate Lighting: Provide sufficient lighting to ensure visibility in all areas, reducing the risk of accidents.

- Ventilation: Maintain proper ventilation to prevent the buildup of fumes and ensure air quality.

Equipment Safety

Material Handling Equipment

- Forklifts: Ensure all forklift operators are trained and certified, and that forklifts are regularly inspected and maintained.

- Pallet Jacks and Carts: Use these tools to reduce manual lifting and strain, and ensure they are in good working order.

Personal Protective Equipment (PPE)

- PPE Requirements: Provide PPE such as gloves, helmets, and safety glasses, and enforce their use.

- Maintenance and Replacement: Regularly check and replace worn or damaged PPE.

Automation and Robotics

- Safety Protocols: Implement safety measures for automated systems, including emergency stop mechanisms and clear safety zones.

- Training: Train employees on the safe operation and interaction with automated equipment.

Employee Training and Awareness

Safety Training Programs

- Onboarding Training: Provide comprehensive safety training for new hires, covering emergency procedures, equipment operation, and hazard identification.

- Ongoing Training: Offer regular refresher courses and updates on new safety protocols.

Emergency Preparedness

- Drills and Simulations: Conduct regular fire drills and emergency response simulations to ensure employees are prepared.

- First Aid Training: Train employees in basic first aid and CPR, and ensure first aid kits are accessible.

Promoting a Safety Culture

- Reporting Systems: Encourage employees to report hazards and near-misses without fear of retribution.

- Safety Committees: Establish a safety committee to regularly review and improve safety practices.

Technology and Safety Innovations

Implement Warehouse Management Systems that support security. These are some of the features to consider.

Safety Management Systems (SMS)

- Digital Tracking: Use SMS to track safety performance, manage incidents, and schedule training.

- Automated Reporting: Implement systems that automatically report and log incidents for compliance and review.

Wearable Technology

- Monitoring Devices: Use wearable devices to monitor employee health and safety, such as heart rate monitors or fatigue trackers.

- Real-Time Alerts: Equip wearables with alert systems to notify workers of potential hazards in real-time.

Conclusion

Warehouse safety is a dynamic and ongoing process that requires commitment from all levels of an organization. By adhering to regulatory standards, investing in employee training, and continuously evaluating and improving safety practices, warehouses can create a safer environment for everyone involved.

Laceup systems are aligned with the procedures leading to safe warehouse operations. If you want to learn more, give us your information to schedule a meeting.

I hope this article has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this video about Product Placement in a Warehouse.

Sorry, the comment form is closed at this time.