What Catch Weight Distributors Need in a WMS

Catch weight is a term used in industries that deal with products sold by weight but whose individual units can vary in size. For distributors handling these types of products, such as meat, seafood, or other perishable goods, managing these variations is crucial to maintaining accurate inventory and ensuring proper pricing. A robust Warehouse Management System (WMS) is essential for efficiently handling weight of products. In this article, I explain what exactly do catch weight distributors need from a WMS, its key features and capabilities.

Key Features for catch weight distributors Management

Support for Variable Weights: The most critical feature that a WMS must have for catching weight distribution is the ability to track and manage products with varying weights. Unlike standard inventory items, where a single unit is counted, catch weight items require the WMS to record the weight of each unit at the time of receipt and again during picking and shipping. The system must be able to handle these variations without causing errors in inventory counts or financial records.

Real-Time Weight Tracking: Catch weight distributors need a WMS that allows for real-time tracking of each product’s weight from receipt to shipment. This ensures that the system is always up-to-date with the latest data, reducing the chances of errors in invoicing, order fulfillment, and stock management. Real-time weight tracking helps optimize operations and maintain accuracy in both the physical and financial records of the business.

Integrated Pricing and Billing: Pricing for catch weight products can be complex, as it’s determined by the weight of the product rather than a standard unit price. A WMS should seamlessly integrate with the business’s pricing system to calculate the correct price for each product based on its weight. This integration should also support the generation of accurate invoices that reflect the correct weight-based charges.

Advanced Inventory Management: For distributors dealing with catch weight products, it’s essential that their WMS can manage not just the inventory by quantity, but also by weight. This feature allows the system to handle inventory adjustments when products are received, picked, or shipped, based on weight rather than quantity. Advanced inventory management ensures that stock levels are accurately maintained, which is especially critical for perishable goods with limited shelf lives.

Lot and Batch Tracking: Many catch weight distributors also need to track products by lot or batch number, which helps with traceability and food safety compliance. A WMS designed for this purpose will allow distributors to track the weight of each batch and monitor the shelf life of products. This feature is particularly important in industries like food distribution, where regulatory requirements demand full traceability from receipt to shipment.

Reporting and Analytics: A WMS with catch weight capabilities should offer comprehensive reporting tools. These tools should provide insights into inventory turnover, weight-based pricing trends, and other key performance metrics. Advanced reporting capabilities allow catch weight distributors to optimize their inventory levels, forecast demand, and ensure that they are maximizing their profitability.

Handling Returns and Adjustments: Returns management is another crucial aspect for catch weight distributors. In some cases, the weight of a product returned may differ from the original weight, requiring adjustments in both the inventory and billing systems. A WMS capable of handling such returns ensures that these discrepancies are managed effectively, helping to maintain accuracy in stock and financial records.

Why a Specialized WMS Is Essential in catch weight distributors

Not all WMS solutions are designed to handle the unique challenges of catch weight products. Standard WMS platforms may struggle with weight-based inventory tracking, resulting in discrepancies in stock levels and pricing. By investing in a specialized WMS that’s built with catch weight handling capabilities, distributors can automate and streamline processes that would otherwise require manual intervention. This not only saves time but also minimizes errors and enhances the efficiency of warehouse operations.

The Return on Investment

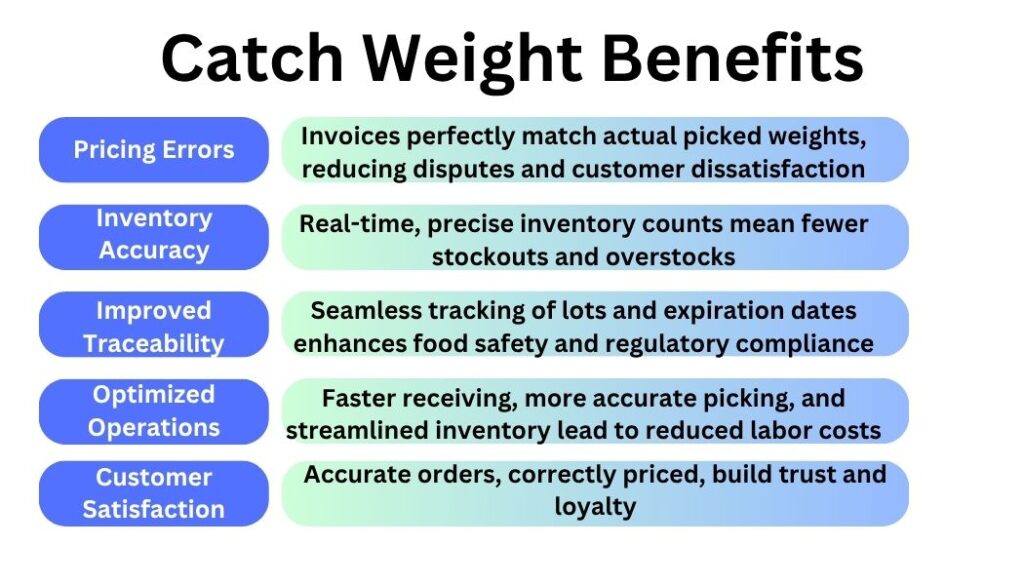

Implementing a WMS tailored for catch weights yields significant benefits that yield a return on investment:

Conclusion

For catch weight distributors, a specialized WMS is not just a luxury, it is a necessity. With the right features like real-time weight tracking, integrated pricing, and advanced inventory management, distributors can efficiently handle the complexities of varying product weights, ensuring accurate inventory, optimized pricing, and compliance with industry regulations. By selecting Laceup WMS that is tailored to catch weight needs, distributors can improve their operational efficiency, reduce errors, and ultimately provide better service to their customers. If you want to learn more about our solutions, contact us.

I hope this article has been helpful to you. I will continue to post information related to management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this recent video on features a WMS must have for proper weight management.

Sorry, the comment form is closed at this time.