Wholesalers are Pivoting from Just-in-Time to Just-in-Case. Why?

For decades, the “Just-in-Time” (JIT) manufacturing and inventory model has been the gold standard of efficiency. Pioneered by Toyota, the goal was simple: minimize waste by receiving goods only as they were needed in the production process. However, the global landscape has shifted. Today, rising transportation costs and high interest rates are forcing wholesalers to abandon the lean JIT philosophy in favor of a more resilient “Just-in-Case” (JIC) model. In this article, I explore why these economic pressures are driving the change and how smarter inventory management is helping wholesalers to adapt, powered by smarter inventory pooling.

The Perfect Storm: Why JIT Collapsed

The transition away from JIT isn’t just a reaction to past supply chain shocks; it is a calculated response to a new economic reality, driven by three factors:

The Death of Cheap Capital: Under JIT, holding inventory was seen as a “liability” because capital was tied up in products sitting on shelves. When interest rates were near zero, the cost of financing that inventory was negligible. Now, with sustained higher interest rates, the cost of debt has skyrocketed. Wholesalers can no longer afford to “guess” wrong, but they also can’t afford the stockouts that lead to lost revenue.

The Volatility of Freight: Transportation costs are no longer a stable line item. Between fluctuating fuel surcharges, labor shortages in the trucking industry, and geopolitical tensions affecting shipping lanes, the cost of moving goods “frequently and in small batches” (the JIT mantra) has become prohibitively expensive.

The “Stockout” Penalty: In a digital-first economy, customer loyalty is thin. If a wholesaler doesn’t have a product in stock, the buyer moves to a competitor in a single click. The cost of a lost sale now far outweighs the marginal cost of holding extra safety stock.

The Resurgence of “Just-in-Case”

Wholesalers are returning to the Just-in-Case model, which prioritizes resilience and availability over absolute leanness. By holding larger buffers of inventory, companies protect themselves against:

- Lead-time variability: Delays at ports or factories.

- Demand spikes: Unpredictable surges in consumer interest.

- Price hikes: Buying in bulk now to hedge against future inflation.

Smarter Inventory Pooling: The Key to Efficient Just-in-Case

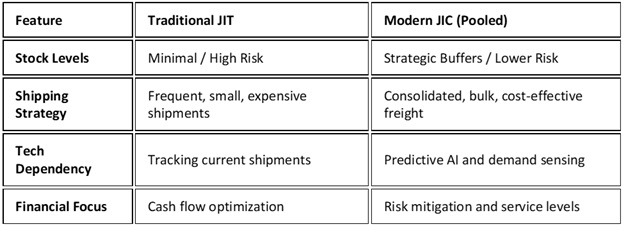

The shift to JIC doesn’t mean reverting to bloated warehouses filled with obsolete stock. Instead, wholesalers are adopting “smarter” strategies like inventory pooling to optimize their buffers. Inventory pooling consolidates stock from multiple locations or suppliers into centralized hubs, reducing overall quantities needed while improving availability. This technique leverages economies of scale: By sharing inventory across regions or product lines, wholesalers can maintain service levels with 10–20% less total stock, mitigating the higher holding costs of JIC. The table compares the behavior of both models.

The Benefits of Pooling

Reduced Total Safety Stock: By pooling inventory for multiple locations, the “law of large numbers” kicks in. The variability of demand in one region often cancels out the variability in another, allowing the wholesaler to hold less total stock than if each warehouse acted alone.

Transportation Efficiency: Wholesalers can move larger volumes less frequently (Full Truckload vs. Less-Than-Truckload), significantly slashing the “cost-per-unit” of transport.

Agility: With a pooled system, inventory can be rerouted from a central hub to wherever the demand is highest, preventing “dead stock” in one region while another suffers a shortage.

Technology Is the Only Way This Works

A JIC model collapses without precision. To make it viable, distributors are deploying:

- AI-driven demand forecasting to recalibrate reorder points weekly, not quarterly

- Dynamic safety stock engines that adjust to freight volatility

- DSD route intelligence that feeds store-level demand back into warehouse planning

- Inventory visibility across the entire network, not just inside each warehouse

This is where modern WMS + DSD ecosystems outperform legacy ERP logic.

Conclusion

The shift from JIT to JIC marks a fundamental change in how the world moves goods. Efficiency is no longer defined by how little you can hold, but by how reliably you can deliver. By combining the safety of “Just-in-Case” with the intelligence of “Inventory Pooling,” wholesalers are finding a new middle ground that survives high rates and expensive roads.

At LaceUp Solutions, we explore how technology transforms distribution, from warehouse management and route optimization to digital sales enablement. Subscribe to the LaceUp Blog for weekly insights on wholesale growth, innovation, and the future of logistics. For more information, please get in touch with us to learn about our solutions.

I hope this article on Just-in-Case have been helpful. I will continue to post information related to management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this video on How To Improve Revenue In your Warehouse Business.

Sorry, the comment form is closed at this time.