WMS Advanced Replenishment Techniques: Optimize Inventory Management

In a previous articles, we learned that a well-executed replenishment strategy can significantly impact a warehouse’s productivity, reduce costs, and improve customer satisfaction. Advanced replenishment techniques powered by Warehouse Management Systems (WMS), offer innovative solutions to optimize these processes. In this article, I will explore some of the advanced replenishment techniques integrated into WMS, focusing on how they can optimize inventory management and streamline warehouse operations.

Understanding Advanced Replenishment Techniques

Advanced replenishment, often referred to as automatic replenishment, is a feature within WMS software that ensures a distributor can effectively stock, reorder, and replenish inventory items. Unlike traditional methods, which rely on manual checks and estimations, advanced replenishment leverages sophisticated algorithms and data analysis to automate the process.

Advanced Replenishment Techniques

Dynamic Replenishment: Dynamic replenishment is a sophisticated technique that adjusts inventory levels based on real-time sales data and demand fluctuations. Unlike traditional systems that rely on static reorder points, dynamic replenishment leverages real-time data to predict demand and make adjustments accordingly. For instance, if a particular product experiences a sudden spike in demand, the WMS will automatically increase the replenishment frequency for that item.

Slotting Optimization-Based Replenishment: Slotting optimization ensures that the most frequently picked items are located in the most accessible areas of the warehouse. In advanced WMS solutions, replenishment can be tied to slotting optimization, ensuring that the most critical inventory is replenished first and stored in the most optimal locations. This approach reduces picking times and boosts overall efficiency.

Automated Replenishment Triggers: Automated replenishment triggers use pre-set conditions to generate replenishment orders automatically. These triggers can be based on factors such as minimum stock levels, order history, or demand forecasts. With advanced algorithms, modern WMS can calculate when stock levels fall below a threshold and automatically trigger an order, ensuring that warehouse managers don’t have to monitor stock levels manually..

Cross-Docking Integration: Cross-docking is a process where incoming goods are transferred directly to outbound shipments, bypassing the need for storage. An advanced WMS with cross-docking capabilities can synchronize replenishment with real-time shipping schedules, reducing the need to store items in the warehouse and accelerating delivery times. This method is particularly beneficial for high-turnover goods and perishable items.

Demand-Driven Replenishment: Demand-driven replenishment relies on forecasting and analytics tools within the WMS to determine optimal stock levels. By analyzing sales trends, seasonality, and customer behavior, the WMS can recommend replenishment quantities that align with future demand. This technique helps to reduce the risk of stockouts and prevents excess inventory buildup.

Just-in-Time (JIT) Replenishment: Just-in-time (JIT) replenishment is an inventory management strategy where items are restocked just before they are needed. This method is particularly useful for high-cost or perishable goods that should not sit idle in the warehouse for long periods. A WMS with JIT capabilities can automate the entire process by syncing replenishment schedules with production or sales cycles, ensuring that inventory levels are maintained at optimal levels.

Wave Replenishment: Wave replenishment is an advanced technique where replenishment is synchronized with picking waves or order processing cycles. In this approach, WMS replenishes the stock that will soon be picked in upcoming waves, ensuring that items are available exactly when needed. This is particularly useful in large, high-volume warehouses where multiple orders are processed simultaneously.

Predictive Analytics for Replenishment: WMS equipped with predictive analytics tools can forecast replenishment needs by analyzing historical data, market trends, and external factors. These predictive models help warehouse managers make data-driven decisions, enabling them to anticipate demand spikes or downturns and adjust replenishment cycles accordingly. The integration of AI and machine learning further enhances predictive accuracy.

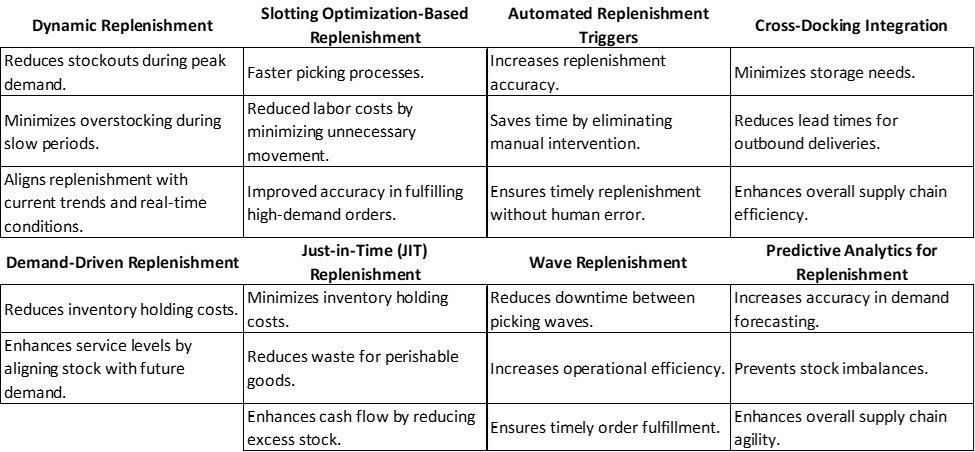

The figure below shows the benefits of each technique.

Conclusion

Innovative technologies and a keen understanding of the variables affecting delivery routes are transforming Direct Store Delivery operations. Laceup Solutions’ suite of products will help you implement some of these strategies, ensuring that your warehouse replenishment process is efficient, cost-effective, and adaptable to real-world challenges. If you want to learn more, give us your information to schedule a meeting.

I hope this article on advanced replenishment techniques has been helpful to you. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. Our channel has a lot of relevant information. Check out this video about replenishment in your warehouse.

Sorry, the comment form is closed at this time.