WMS Implementation at Arctica: a successful case study

We have talked before about the importance of being prepared for your WMS implementation in “Guidelines to get a successful WMS implementation”. But each warehouse is different and, no matter how well prepared you are, there will always be situations derived from the way this specific warehouse operates, which will cause the implementation team to make corrections and adaptations on the fly. In this article I will walk you through all the problems we had to overcome for a successful WMS Implementation we did at Arctica, one of the largest ice cream factories.

Situations with Inventory count

In any WMS implementation the most difficult part include labeling all the bin locations and then doing your very first inventory count. When you implement locations in your warehouse, having to go through and count the product content within each location can be very difficult. In the case of Arctica we had to do three physical inventories.

- The first physical inventory was interrupted because the power within the warehouse continuously went off (external situation).

- In the second attempt we were able to make a successful count but, due to some constraints in our first in first out functionality that I explain in the next section, we decided to discard the collected data (customization factor).

- It wasn’t until the third inventory, after customizations made to the FIFO, that we were able to count the inventory in the bins and actually have real inventory in place.

Situations with receiving

Once the inventory is in the system, the next thing to do is he receiving through the scanners. The main problem we faced in this phase was related to lot numbers and expiration dates. In Arctica the lot numbers are associated with the pallet but the expiration date is on the product; so, to print both on the tag to be placed on the pallet, they would have to break all the pallets. Since we are a solution provider, we have a high degree of flexibility to adjust the system to customer needs. In this case what we did was match both, the expiration and the lot number, so that they were identical. This solution is OK because Arctica is not a manufacturer, so they do not need to have strict lot traceability rules. What is important for them is maintaining first in and first out.

Situations with put away

Once the product has been received and tagged, it must be placed in the bin position designated by the system, and this is when we encountered the next problem in the WMS implementation. WMSs are typically strict when it comes to FIFO policies so, if they are going to put a new pallet into a bin that has product with an older expiration date, the system is normally going to prompt you to transfer that pallet down before putting away the pallet that you currently have on your forklift. However, for Arctic, expiration is not an issue because the rotation is very high. Therefore, following the standard FIFO policy will increase movement within the warehouse, slowing down rotation. What we did was remove all FIFO restrictions, so they can put away products in any bin at any time.

Situations with Picking

In picking we struggled because we realized that when a person with a big glove went into a freezer to scan a bin location, they were unable to use that big glove to hit seven taps on a screen to confirm an amount. What we did to address this constraint was to compare the quantity scanned in the bin with what is in the order, and if the order can be filled with the existence in the bin, the system automatically takes that as picked. The drawback of this solution is that a picker might pick the wrong quantity. However, with the policies outlined in our article on cycle counting, this error will be minimized. With this fix, we not only resolved the constraint, but the customer could define the pick with a single scan simplifying their picking process.

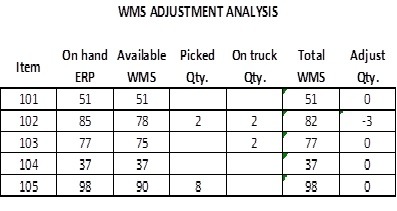

Inventory adjustment

The last issue we had to handle with Arctic, even after the WMS implementation was done, was: how to determine if there is a difference between our system and the ERP used by Arctic? What happens is that their ERP holds the total inventory on hand, whereas Laceup WMS has the detail. Let me explain: the ERP can show that there are 100 of an item on hand. The WMS might show that it has the same 100 but distributed over 5 bin locations. In this case there is no problem since both numbers coincide. But what if there is a difference? If the difference is real then an adjustment in either of the two systems must be executed, but what happens if the difference is because there are transactions carried out in the WMS that are still pending to be done in the ERP? If we adjust, then we will be creating a real discrepancy instead of solving one. To solve this issue, we ended up building an additional module that performs these calculations.

I hope this article has been helpful to you when it comes to the implementation of your WMS. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. If you are interested in this article or want to learn more about Laceup Solutions, please subscribe to stay updated on future articles.

There is a lot of relevant information on our channel. Check out this video on the subject.

Sorry, the comment form is closed at this time.