WMS renders warehouse employees training more efficient

Warehouse staff turnover can be high and every time you need to replace a warehouse position you have to spend a significant amount of time training and mentoring the new employee. In today’s article I will talk about how a Warehouse Management System (WMS) can make warehouse employees training more efficient.

Why warehouse employees training?

It typically takes eight months for a newly hired warehouse employee to reach full productivity, and the latest figures from the Bureau of Labor Statistics put annual warehouse turnover rates at 43%. Considering that the warehouse operation is the heart of any distribution and industrial company, hence the importance of an effective warehouse employees training program. Warehouse employees who are not properly trained lead to costly mistakes and high reprocessing time. This is why you must devote all available resources to ensuring your new hires are well-trained by the time they start doing their job, and a good follow up process aimed at reducing errors along the learning curve.

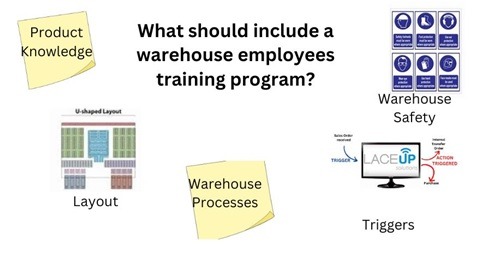

What should a warehouse employees training program include?

A good warehouse employees training program must have two goals:

- Provide the right operating knowledge.

- Reduce turnover by helping them understand that their work is crucial to the company’s success.

On the operation side a training program must provide the following knowledge:

- Product knowledge: categories, presentations and special conditions.

- Layout knowledge: Where the products are located and the criteria for product allocation.

- Operational procedures: how to carry out the different warehouse activities, such as receiving, picking, transfers, etc.

- Trigger activities such as cycle counts, internal transfers, picking list, etc.

- Safety protocols.

How a WMS makes a warehouse employees training more effective?

There are three features that a good WMS has that reduce training time and diminish the errors during the learning process.

Feature 1: Scan capacity

Much of the warehouse employees training time is spent in getting to know the different product categories and presentation; and most of the errors a new warehouse employee makes during the learning curve stem from misidentifying the product, either when receiving a purchase order or while picking a new order. But if your WMS uses scanners to move products in and out of your warehouse, the system will validate if the person is picking the right product, regardless of the employee‘s depth of product knowledge.

Feature 2: Trigger capacity

The second most time consuming activity during the training and learning process is where the products are located and in what order to pick them. The bin sequence tells your employee what sequence to run up and down the warehouse. This feature should be a fundamental part of a warehouse management system because it makes your employees as effective and efficient as humanly possible and, the more time they can save walking up and down your racks, the more money they put in your pocket and the more production they can output.

Feature 3: Bin sequence

The last process in a warehouse operation that takes a long time for a new employee to assimilate is what to do when an event occurs that requires executing a specific task. A WMS that has triggers built in eliminates the need to learn that by heart. We talked about triggers in a recent article. What triggers do is allow your new staff to open up a list of tasks, select the tasks they want to do and go execute them. Triggers help automate their flow and tell them exactly what to do during their job.

I hope this article has been helpful to you when selecting a WMS. I will continue to post information related to warehouse management, distribution practices and trends, and the economy in general. If you are interested in this article or want to learn more about Laceup Solutions, please subscribe to stay updated on future articles.

There is a lot of relevant information on our channel. Check out this video on the subject.

Sorry, the comment form is closed at this time.